Proactive Maintenance, Powered by AI

Remote monitoring systems have transformed equipment maintenance in unimaginable ways — minimising errors and bringing efficiency, ultimately increasing availability. What the emergence of AI and machine learning on the scene has done is fundamentally shift how remote monitoring systems function by adding a layer of intelligent decision-making to data collection.

Historically, remote monitoring systems have been just passively logging sensor inputs — identifying patterns and enabling maintenance teams to react to them. However, instead, taking the game further, AI-enabled remote systems can perform three functions — identifying patterns, detecting anomalies, and even predicting failures before they occur.

From reactive to proactive real-time monitoring

In essence, what value does machine learning add to predictive maintenance for industry?

In practical terms, for instance in mining, the integration of machine learning means real-time monitoring becomes proactive rather than reactive, Ramjack’s Katrina Wertheim elaborates. “Key areas where we recently are seeing AI making an impact include analysis for predictive maintenance, fuel efficiency, operator performance, and productivity monitoring. Machine learning algorithms constantly refine themselves, learning from both historical and live data to provide increasingly accurate insights over time. This ultimately turns vast data sets from equipment and operational environments into actionable intelligence when properly integrated across your mine site.”

Safety and equipment availability

The addition of machine learning to remote monitoring is very significant from safety and equipment availability perspectives. The ability to predict potential failures before they happen has a direct and measurable impact on both safety and uptime, Wertheim says, highlighting two points, as identified consistently in their rROC (Ramjack’s Remote Operations Center).

From a safety perspective, AI-driven alerts can identify dangerous trends — like overheating brakes or unstable ground conditions — long before they reach critical levels. As a result, operators and managers can intervene early, reducing the risk of equipment failure-related incidents.

From an availability standpoint, AI helps minimise unplanned downtime by ensuring maintenance is conducted only when necessary, rather than on fixed schedules. This keeps high-value equipment running efficiently for longer stretches and maximises asset utilisation without compromising safety.

Integrating AI and machine learning into existing remote monitoring

For a practical industry application, Wertheim references how Ramjack is utilising AI and machine learning opportunities to help clients achieve optimal equipment safety and efficiency. “At Ramjack, we work closely with our technology partners and our mining customers to integrate AI and machine learning into their existing remote monitoring solutions through our rAIL program (Ramjack’s Artificial Intelligence Lab). For example, our real-time data integration platforms allow us to marry equipment telemetry with contextual data — such as environmental conditions or operator behaviour — so machine-learning models can deliver hyper-relevant insights,” she demonstrates.

Ramjack leverages predictive analytics for critical assets like mobile equipment. This enables mines to forecast component failures, reduce maintenance costs, and avoid unnecessary shutdowns. “Our approach isn’t just about deploying AI. In particular, it’s about integrating the right AI for the specific challenges faced by our customers, always with a focus on practical outcomes and measurable ROI,” Wertheim expounds.

Another area where the marriage of AI and machine learning is having a marked impact is in facilitating ESG reporting compliance.

In jurisdictions worldwide, ESG requirements are becoming more stringent and data-heavy. In this environment, AI is proving essential in helping mines stay compliant and transparent, Wertheim states, citing two examples. “AI can aggregate and analyse data from multiple systems — ventilation, energy usage, water management, and more — to provide real-time ESG insights. Machine learning models can also identify deviations from compliance baselines and automatically flag them for review or corrective action. For example, if emissions suddenly spike beyond acceptable thresholds, an AI system can alert relevant stakeholders and even trace the issue back to a specific piece of equipment or operational condition. This level of data granularity and automation makes it far easier for mining companies to meet ESG reporting obligations with accuracy, consistency, and confidence.”

If African mining operations and related industries embrace the marriage of machine learning and remote monitoring, Ramjack believes they will achieve more through improved safety, equipment availability, and improved compliance.

Ramjack is the provider of remote equipment monitoring solutions and technology integration services to various industries worldwide. The company considers Africa as one of its biggest markets.

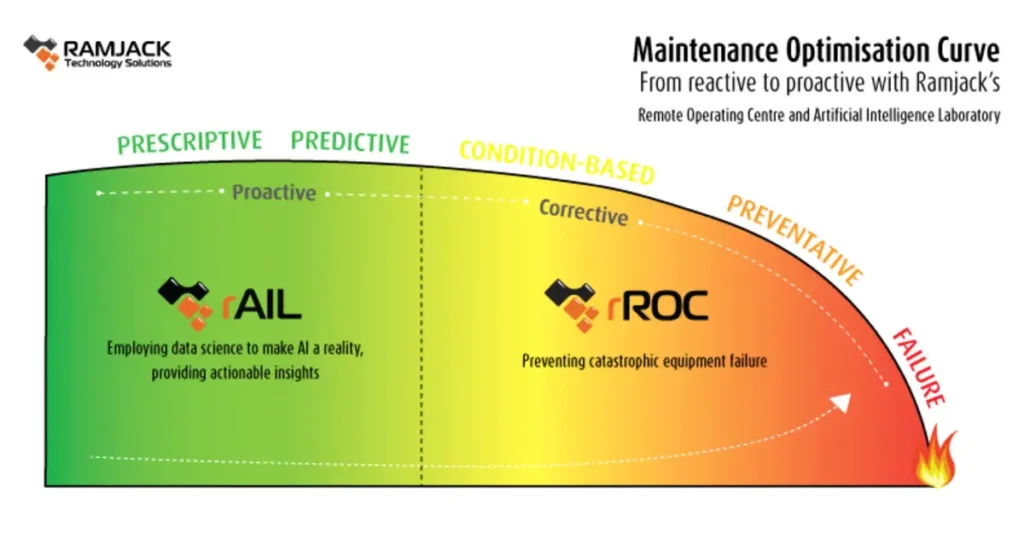

Maintenance Optimisation Curve: From reactive to predictive. This chart highlights how Ramjack finds that integrating a Remote Operations Center and an AI Lab transforms maintenance—from responding to machine failures to proactively preventing them—through real-time insights, pattern recognition, and prescriptive recommendations that drive equipment reliability and performance.

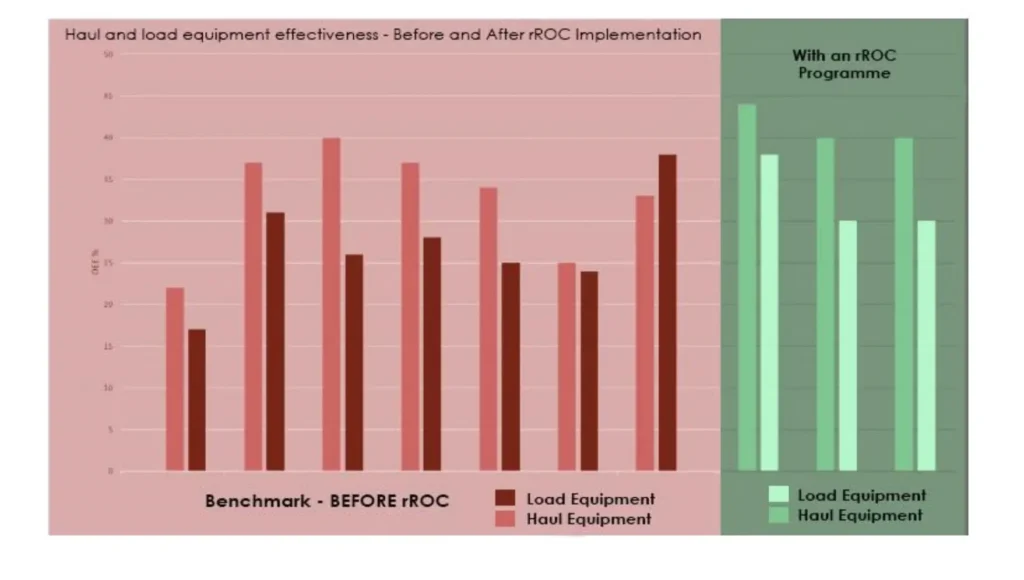

Significant improvement in Overall Equipment Effectiveness (OEE) for load and haul operations after implementing Ramjack’s Remote Operations Center — driven by increased utilization, reduced downtime, and smarter dispatching in action.

Ramjack’s Artificial Intelligence Lab is a specialised service for any mine that has deployed technology systems. A team of computer scientists, data analysts and experienced mining engineers, dedicated to studying the data from your mine’s technology systems, identify and unlock bottlenecks. The rAIL identifies trends, unveils areas for improvement, and delivers insights significant enough to have proven ROI within one budget cycle.